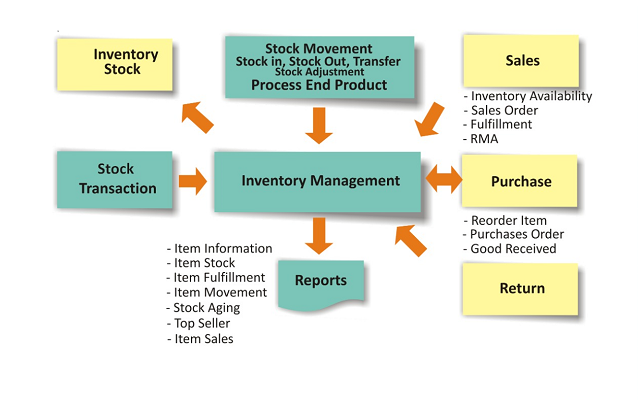

An efficient and effective inventory management solution is key to making sure your inventory are managed well and business remains profitable. We try to ease this complicated task with our latest Inventory Management solution.

We have automated the process in our solution to track the exact stock quantity and cost of all the items you have in your store/warehouse, as well as how inventory is moving in and out.

Our physical count process helps to check and maintain the accuracy of your inventory in system. We use most common methods for cycle counting for physical inventory count involves specifying a set of inventory to physically count on periodic basis, and comparing those numbers with the records in your inventory management system.

- Product Management

- GRN Process

- Fulfilment & Shipment

- Inventory Replenishment

- Inventory Re-Order

- Location wise Stock Movement and Adjustment

- Physical Inventory Counts